0769-8219-8759

0769-8219-8759

导语:流水线生产是一种高效的生产方式,可以提高生产效率和产品质量。在东莞,如何实施高效的流水线生产呢?本文将从流水线生产的优势和实施原则两个方面展开介绍。

一、流水线生产的优势

1. 提高生产效率:流水线生产将产品的生产过程分解成多个独立的工序,每个工序由专责的员工完成,大大减少了生产时间,提高了生产效率。

2. 降低生产成本:流水线生产可以减少员工之间的沟通和调度时间,从而减少了延误和错误的发生,降低了生产成本。

耀世娱乐3. 增加产品质量:由于每一个工序都由专门的员工完成,流水线生产可以确保每个环节的质量,最终提高产品的质量。

耀世娱乐二、流水线生产的实施原则

耀世娱乐1. 合理的流程规划:在实施流水线生产前,需要对生产流程进行仔细规划,确定每个工序的顺序和工时,确保流程合理、高效。

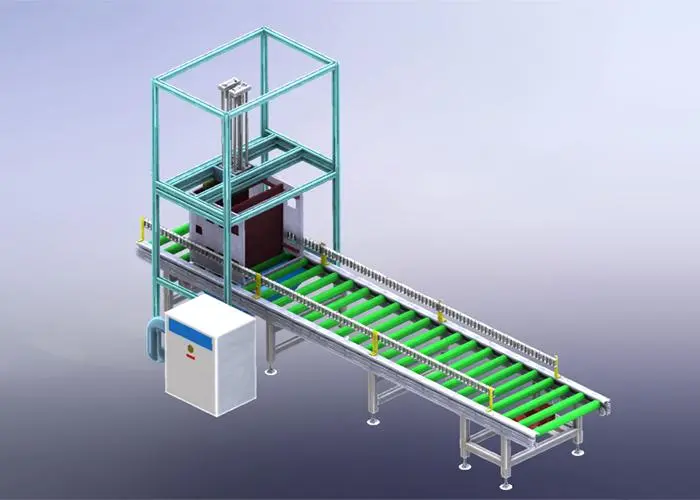

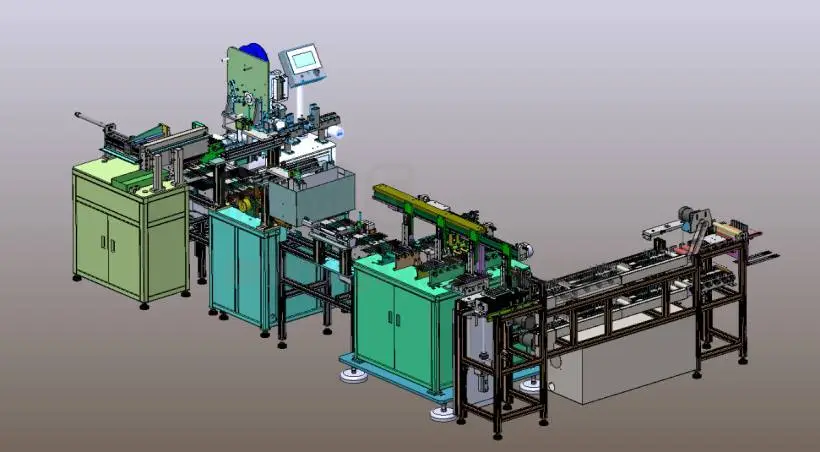

2. 优化设备配置:流水线生产需要使用专门设计的设备,对设备进行合理配置可以使生产效率得到更大化。例如使用自动化设备、机器人等。

3. 培训和激励员工:流水线上的每个员工承担不同的工序任务,所以需要通过培训,使员工对自己的工序熟练掌握。同时,通过激励措施,提高员工的积极性和效率。

总结:流水线生产在提高生产效率、降低生产成本以及增加产品质量等方面具有明显的优势。在实施流水线生产时,需要合理规划流程、优化设备配置,并注重培训和激励员工。这些原则将有效地帮助东莞企业实施高效的流水线生产。Flow assembly production is an efficient manufacturing system to improve production efficiency and product quality. How to implement efficient flow assembly production in Dongguan? In this article, we will discuss the advantages of flow assembly production and the principles to implement it.

耀世娱乐【1】Advantages of flow assembly production

Flow assembly production provides several advantages:

耀世娱乐1. Improved production efficiency: Flow assembly production breaks down the production process into multiple independent steps, and each step is carried out by dedicated workers. This greatly reduces production time and enhances efficiency.

2. Reduced production cost: Flow assembly production reduces communication and scheduling time among workers, minimizing delays and errors, which helps to decrease production costs.

3. Enhanced product quality: With dedicated workers completing each step, flow assembly production ensures quality at every stage and ultimately improves product quality.

【2】Principles to implement flow assembly production

To implement flow assembly production effectively, the following principles should be applied:

1. Rational process planning: Prior to the implementation, careful planning of process flow is essential, including determining the sequences and timing of each process to ensure a smooth and efficient workflow.

2. Optimized equipment configuration: Flow assembly production requires specially designed equipment. Proper configuration of the equipment can maximize production efficiency, such as using automated machines or robots.

3. Training and motivating employees: As each worker is responsible for a specific task on the assembly line, thorough training is necessary to ensure their proficiency in their respective processes. Additionally, implementing motivational strategies can increase employee productivity and morale.

耀世娱乐【Conclusion】

Flow assembly production provides obvious advantages in improving production efficiency, reducing costs, and enhancing product quality. To implement flow assembly production effectively in Dongguan, it is important to plan the workflow intelligently, optimize equipment configuration, and emphasize training and motivating employees. Applying these principles will assist Dongguan companies in achieving efficient flow assembly production.